0086 13635632360

0086 13635632360

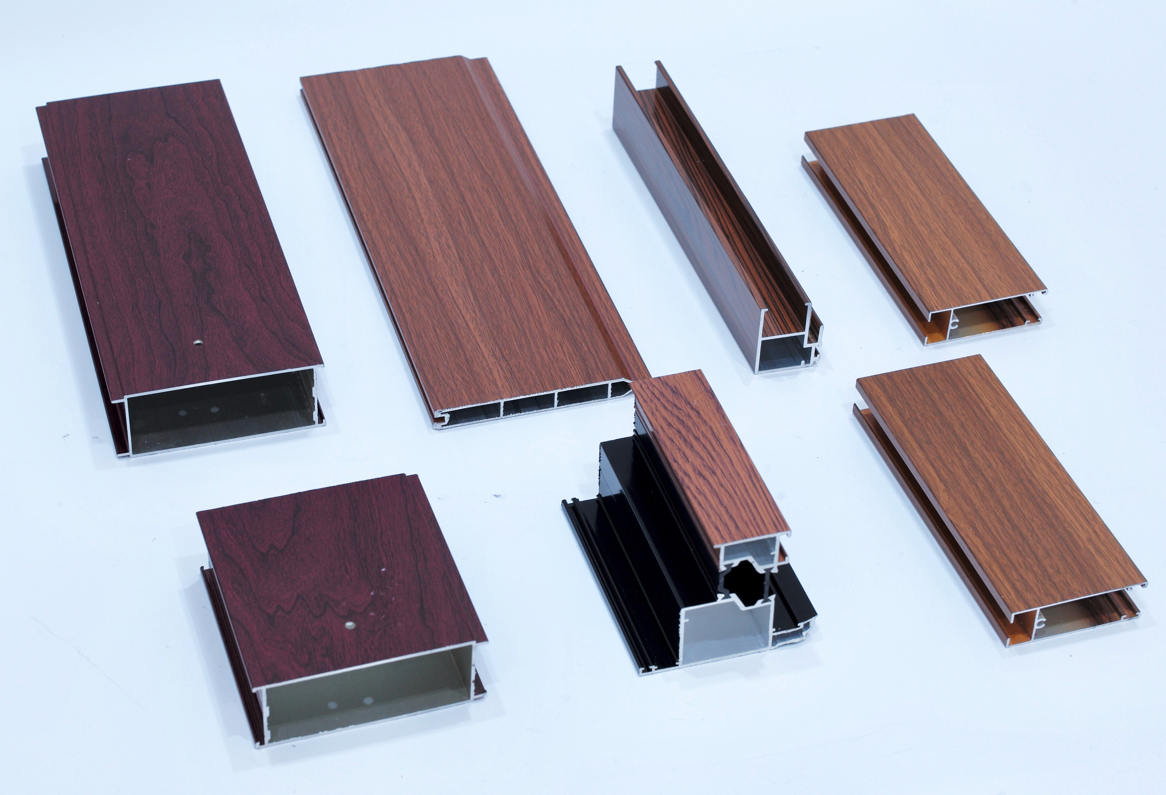

Broken bridge thermal insulation aluminum door and window is also called broken bridge aluminum, thermal insulation aluminum alloy, and broken bridge aluminum alloy. Both sides are made of aluminum, and the middle is made of plastic profile cavity as thermal insulation material. This innovative structural design takes into account the advantages of both plastic and aluminum alloy materials, while meeting various requirements for decorative effects, door and window strength, and aging resistance. The principle of Broken bridge thermal insulation aluminum alloy is to insert a thermal insulation strip in the middle of the aluminum profile to break the aluminum profile to form a broken bridge, which effectively prevents the conduction of heat. The thermal conductivity of insulated aluminum alloy profile doors and windows is 40-70% lower than that of non-insulated aluminum alloy profile doors and windows. Broken bridge aluminum is made of door and window frame fans, equipped with insulating glass, hardware, screens, glass glue, styrofoam, sealing strips, etc., and the door windows processed in this way are called broken bridge insulated aluminum doors and windows profile. ◆ ◆ ◆ Analysis of the advantages of thermal insulation aluminum for broken bridges: 1. Broken bridge thermal insulation aluminum has good thermal insulation. The inner and outer frames of the heat insulation profile are softly combined, and the frame is sealed with EPDM tape, which is tightly closed, has excellent air and watertight performance, and has superior thermal insulation performance; the window sash adopts hollow glass structure, so that the window truly shows sound insulation and insulation. It has excellent heat, heat preservation and functions, and saves a lot of heating and cooling costs. The heat transfer coefficient K value is tested to be below 2.23—2.94w/2K. The energy saving effect is significant. The energy saving cost of several years is enough to make up for the initial investment. 2. The thermal insulation aluminum waterproof function of the broken bridge. Utilizing the principle of pressure balance, a structural drainage system is designed with drainage outlets for smooth drainage and good water tightness. 3. The thermal insulation aluminum of the broken bridge prevents condensation and frost. Broken bridge aluminum profiles can achieve three-way sealing structure for doors and windows, and most of them can even achieve 8 sealings, reasonably separate the water vapor cavity, successfully achieve equal pressure balance of air and water, significantly improve the water tightness and air tightness of doors and windows, and achieve clean and bright windows. Effect. 4. Design of thermal insulation aluminum mosquito screen window for broken bridge. The invisible screen window can be installed and used inside and outside. It is anti-mosquito and flies, especially suitable for mosquito-prone areas in the north. You can a...

Read More

The importance of industrial aluminium profile to industrial production is self-evident. This light-weight and high-load-bearing material has become a generalist in industrial production. Although people are no strangers to aluminium extrusion profiles, many customers do not know that industrial aluminium extrusion profiles are extruded through an extruder and are also extruded aluminium profiles. Let's take a look at the aluminium extrusion process. 1.The principle of industrial aluminium extrusion "Extrusion" is a plastic processing method that applies external force to the metal blank placed in the container (extrusion cylinder) to make it flow out of a specific die hole to obtain the desired cross-sectional shape and size. 2.The composition of the industrial aluminium extrusion press The extruder is composed of a machine base, a front column frame, a tension column, an extrusion cylinder, and a hydraulic system under electrical control. It is also equipped with a mold base, thimble, scale plate, slide plate, etc. 3. Classification of industrial aluminium extrusion profile methods According to the type of metal in the extrusion cylinder, the state of stress and strain, the direction of extrusion, the state of lubrication, the temperature of extrusion, the speed of extrusion, the type or structure of molds, the shape or number of blanks, the shape or number of products, etc. Different, can be divided into forwarding extrusion method, reverse extrusion method, (including plane deformation extrusion, axisymmetric deformation extrusion, general three-dimensional deformation extrusion) lateral extrusion method, glass lubrication extrusion method, hydrostatic Extrusion method, continuous extrusion method, etc.

Read More

With their advantages, industrial aluminum profiles are favored by various manufacturing industries, including automation technology manufacturing industries, logistics companies, automobile manufacturing, food companies, and chemical manufacturing industries. Different manufacturing industries have different products, and they can carry out flexible design schemes based on production requirements. This product is the actual main purpose of industrial aluminum profiles. Let's explain to everyone in detail what aluminum profile frame products can be built with aluminum profiles? 1. Workbench. Most of every manufacturing industry uses workbenches, which can also be called office desks or workbenches. There are many types of workbenches, and the natural environment for different types of workbenches is different. For example, the antistatic workbench can be used in the electronic device semiconductor material processing plant, and the production assembly line workbench can be used in the transfer wiring. Industrial aluminum profiles also have a fluent strip workbench that cooperates with the application of automatic sorting equipment, which can ensure the first-in-first-out method of objects. 2, guardrail partition. The guardrail partitions the application area, which is convenient for the management and maintenance of equipment and staff safety. With different control panels, it can be used in different working environments. 3. Protective cover for mechanical equipment. Some mechanical equipment does not have a protective cover. It is very easy to have accidents in the application. At this time, it is necessary to install the main box or protective cover. The industrial aluminum protective cover is beautiful and generous and has high safety. 4. Structure support frame. For industrial equipment or instrument equipment to have a support point of the base, it is necessary to customize the structure or support frame and install a universal wheel at the bottom to complete the movement. For example, the conveyor structure is made of industrial aluminum profile, which is convenient and quick to assemble and disassemble. 5. Ascending ladder maintenance service platform. The key is used in aerospace, high-speed train maintenance, mechanical equipment maintenance, etc. The overall frame shear wall is made of industrial aluminum profiles, with a load capacity of 2000-3000KG, and with different footboards, it can be used in different venues. 6. Storage racks/material racks. Whether it is the warehouse logistics manufacturing industry or other industries, the application of storage shelves is inevitable, and it has the effect of managing objects, clean and orderly. 7. Whiteboard rack display shelf. The whiteboard rack made o...

Read More

Qualified industrial aluminum profiles should have a smooth and beautiful surface. However, with the increasing demand for industrial aluminum profiles from enterprises nowadays, many aluminum profile manufacturers with uneven technical levels continue to emerge. Many industrial aluminum profile processing manufacturers have been producing aluminum profiles with sassafras, scratches, and bumps due to their strength and insufficient production and management. What are the reasons for the surface damage of industrial aluminum profiles? 1. There are impurities or segregation of ingot components on the surface of the ingot. There are a certain amount of hard metal particles in the ingot. When the metal flows through the working belt during the extrusion process, these segregation floats or hard metal particles adhere to the surface of the working belt or cause damage to the working belt, and cause damage to the surface of the profile. Scratches; 2, when the fork rod sends the profile from the discharge rail to the swing bed, the profile will collide due to the excessive speed; 3. There is debris on the mold cavity or the working belt, and the hardness of the working belt of the mold is low so that the surface of the working belt is injured during extrusion and scratches the profile; 4, artificially dragging industrial aluminum profiles on the swing bed to cause scratches; 5. There are bare metal or graphite strips on the discharge track or swing bed with hard inclusions, which will scratch the surface of the industrial aluminum profile when it comes in contact with the profile; 6. The friction or extrusion between the profiles during transportation causes damage.

Read More

Common aluminum profiles include architectural profiles, decorative profiles, and industrial aluminum profiles. Each category of aluminum profiles includes a variety of specifications and models. The 6063-T5 series aluminum profiles are most used in the industry. For users, how to choose The use of a suitable model is a very important issue. The following aspects can be used as a reference for the selection of industrial aluminum profiles. 1. Strength Strength is an important index to measure the load-bearing capacity of industrial aluminum profiles. It refers to the maximum deformation capacity of industrial aluminum profiles that break or exceed the allowable limit after being loaded. From a mechanical point of view, it includes tensile strength, compressive strength, and yield resistance. Strength etc., is the basic requirement that every aluminum profile must meet. Customers can give the type of industrial aluminum profile required according to their product needs and the corresponding load-bearing capacity. The manufacturer can calculate the static load and no-load of the industrial aluminum profile according to the calculation formula of the deformation of the aluminum profile. The amount of deformation in the case of, including the maximum allowable bending stress of industrial aluminum profiles. The amount of deformation is an important basis for selection. According to the range of deformation, determine whether the type of industrial aluminum profile can meet the load required by customers If the capacity cannot be achieved, choose a profile with a larger load-bearing capacity or increase the load-bearing capacity by changing the frame structure. Different types of industrial aluminum profiles have different unit mass and moment of inertia, so the load-bearing capacity is different. You can also follow the designer’s suggestions and comprehensively consider the mechanical properties and cost performance to help customers choose the length and model of industrial aluminum profiles. 2. Use environment The use environment of the product is also an important basis for selection. The industrial aluminum profile undergoes melting, extrusion, casting, and oxidation coloring processes during the production process, and sandblasting oxidation, anodization and electrophoretic coating are carried out based on the original oxide film. And other surface treatment processes, so that its surface coating can reach 12μm or more, whether it is worn resistance and corrosion resistance, or high-temperature resistance and weather resistance are very good, can be applied to various harsh industrial production environments, customers can According to the production conditions of your workshop, choose the required industrial aluminum profile model. If it is a high temperature and corrosive production workshop, choose the 6063-T5 model industrial aluminum profile to be the most durable. If it is produced at room temperature and in relatively good p...

Read More online service

online service 0086 13635632360

0086 13635632360 sales@sxalu.com

sales@sxalu.com 008617309695108

008617309695108