0086 13635632360

0086 13635632360

ANHUI SHENGXIN ALUMINIUM CORPORATION LIMITED is located in Xuancheng City,Anhui Province,China,which is 100km from Wuhu port and 350km from Shanghai port.

As a foreign trade company integrating industry and trade,we can provide you an Accurate delivery time limit, quality products, professional service.Our enterprise registered capital is 103.6371 million yuan and total assets is 358 million yuan, covers an area of 189,000 square meters. We are the largest aluminium profiles enterprice of our province. Shengxin has more than 40 modern production lines such as smelting casting, extruding, anodizing , powder coating, electrophoresis coating, fluorocarbon coating, wood grain transfer printing, environmental protection and energy saving thermal insulation bridge cut .Especially the 5500T extrusion line, it is the one of the largest production line in east China .Our annual output is sixty thousand tons of aluminum profile production. In 2018, the company ’s output value exceeded 800 million yuan!

Extrusion Workshop

Anhui Shengxin Aluminum Co., Ltd. has 35 extruders, including a 5500T extruder and a 2500T extruder. With an annual production capacity of 60,000 tons of aluminum profiles. The company adopts advanced automatic production technology and perfect quality management system to bring you high-quality aluminium profile products.

Extrusion Workshop

Extrusion Workshop

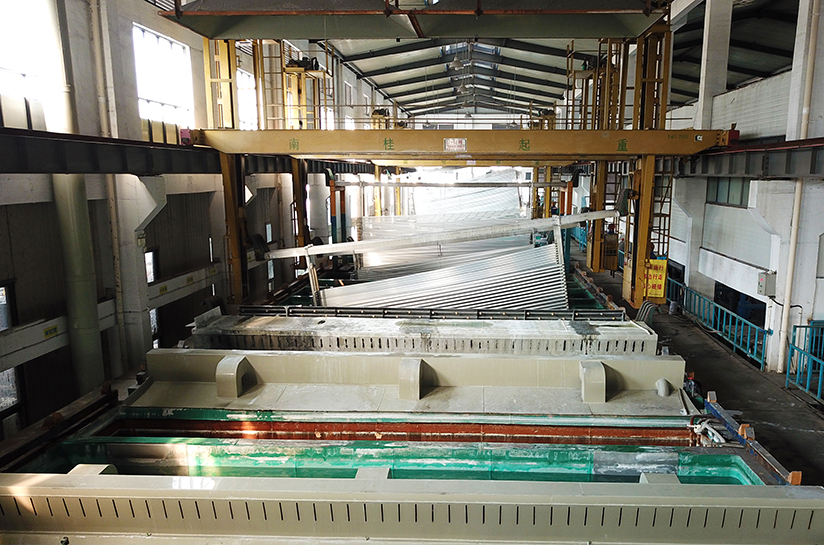

Anodizing workshop

Anodizing is a process to produce aluminum oxide coating on the profile's surface, so as to protect it form natural oxidizing, thus enhance its hardness and durability against different weather conditions.

Process flow:

(1) Anodizing of silver-white and silver-white electrophoretic :

Upper shelf - washing - low temperature polishing - washing - washing - clamping - oxidation - washing - washing - washing - washing - washing - sealing - washing - washing - off shelf - air drying - testing - entering electrophoresis process - packaging

(2) Anodizing of abrasive and abrasive electrophoretic :

On-shelf-degreasing-washing-acid-washing-washing-washing-alkali-washing-washing-washing-water-washing-neutralizing light-washing-water washing-water washing-water washing-forceps-oxidation-washing-water washing-water washing-sealing-water washing-washing-water washing-off-shelf-air drying-testing-packaging-entering Enter electrophoresis process

(3) Anodizing of dyes and electrophoretic dyes:

Up shelf-washing-low temperature polishing-washing-washing-washing-clamping-oxidation-washing-washing-washing-washing-washing-washing-coloring-washing-sealing-washing-washing-washing-washing-washing-testing-entering electrophoresis process

—— Off-shelf - Air-drying - Inspection - Packaging

Anodize Oxidation workshop

Anodize Oxidation workshop

Anodize Oxidation workshop

Anodize Oxidation workshop

Anodize Oxidation workshop

Powder Coating workshop

Powder coating is a process to coat the aluminum profiles with a synthetic powder of a wide range of colors.Aluminum profile surface is degreased to remove oils and greases firstly. Any present oxide layer is etched by dipping the profiles in an acid activation tank. Profiles are then rinsed with deionized water to remove any remaining chemicals. Now the profiles are ready to undergo the chemical conversion coating.Shengxin Anhui has four Powder Coating lines, including horizontal spraying and vertical spraying.

Powder Coating technology for aluminium profiles and requirements for powder spraying construction technology and requirements The so-called powder electrostatic spraying is based on the principle of high voltage electrostatic corona electric field. High voltage negative pole is connected to the metal diversion mark of the spray gun head, and the spray workpiece is grounded to form a positive pole, which forms a strong electrostatic electric field between the spray gun and the workpiece. When powder coatings are sent from powder barrel to the guide rod of spray gun as compressed air carrying gas, the corona discharge produced by the high voltage negative electrode connected to the guide rod generates dense negative charge near the guide rod, which makes the powder charged negatively and enters into the electrostatic field with high electric field intensity, in the electrostatic force and transportation. Under the dual action of gas, the powder evenly flies to the surface of grounding workpiece to form a thick and thin uniform powder layer, which is then cured by heat and transformed into a durable coating. Painting construction process: pretreatment - drying to remove moisture - spraying - Inspection - baking - Inspection - finished products.

Powder Coating workshop

Powder Coating workshop

Powder Coating workshop

Powder Coating workshop

Powder Coating workshop

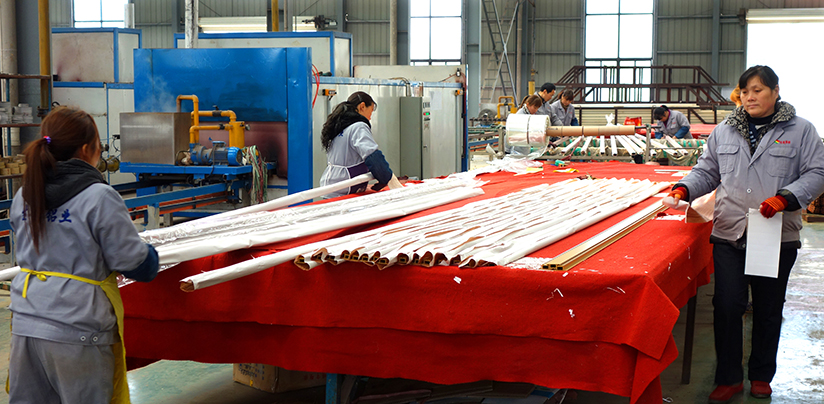

Wooden Grain Transfer workshop

Wood grain transfer printing is a process of heat sublimation of ink on transfer printing or transfer film and penetration into coating by vacuum wood grain transfer equipment after electrostatic powder spraying on metal material and under high temperature pressure.

Wooden Grain Transfer workshop

Wooden Grain Transfer workshop

Wooden Grain Transfer workshop

High Deep Process

High Deep Process workshop

High Deep Process workshop

online service

online service 0086 13635632360

0086 13635632360 sales@sxalu.com

sales@sxalu.com 008617309695108

008617309695108