0086 13635632360

0086 13635632360

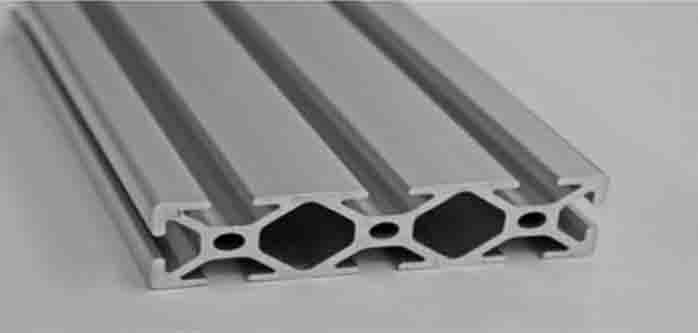

In our life, industrial aluminum profiles can be seen everywhere. Industrial aluminum profiles are used in many because of their good formability and processability, and the surface is covered with oxide film, which is beautiful and durable, anti-corrosion and wear-resistant, and can be recycled. In each industry field, what are the specific industries that use more industrial aluminum profiles? 1. Solar photovoltaic industry: it can be used to make solar photovoltaic brackets, solar aluminum profile frames, etc.; 2. Electronic and electrical industry: used for workbenches, consoles, etc. that need to be used in various electronic component factories; 3. Large-scale escalator maintenance platform: such as airport platform, equipment maintenance platform, factory cross-barrier cross-ladder, climbing ladder escalator, etc.; 4. Equipment protective cover: various mechanical equipment dustproof sealing covers, product display cabinets; 5. Workshop production line: various intensive enterprise production lines, workstation consoles, assembly line workbenches, conveyor belts, conveyor belts; 6. Safety fence: various industrial aluminum safety fences, regional partitions, screens, industrial fences; 7. Shelf material rack: various racks, shelves, material racks, display racks, material turnover carts, aluminum work cart trolleys, fluent shelves; 8. Frame structure: various equipment aluminum profiles, racks, brackets, equipment columns; 9. Automobile manufacturing industry: it can be used for car body manufacturing and model frame manufacturing; 10. Radiator products: can be used for the production of various radiator products; 11. Aluminum alloy profiles for rail vehicles. Frames around orbital stations and more. 12. Aluminum profiles for medical equipment. Equipment frames, equipment accessories, medical stretcher beds, etc.

Read More

In the decoration market now, broken bridge aluminum doors and windows are relatively common, and more and more families choose to install it. So what advantages does it have? Let's find out~ The benefits of broken bridge aluminum doors and windows 1. Compared with other ordinary windows, it is more sturdy, so when it is windy and rainy, it can withstand strong winds. Even if the building vibrates, the doors and windows will not be damaged by shaking. 2. The heat insulation effect is more prominent, because the heat insulation material is added to the aluminum profile, so it has the effect of heat insulation. In summer, it can be clearly felt that the indoor temperature is slightly lower than that of the outdoor. 3. Good sound insulation effect. Because its sealing performance is very good, the sound insulation effect is also very prominent, which can reduce the decibel outside. If you want to achieve good sound insulation, you can install broken bridge aluminum windows. 4. The appearance is high, and there are many colors to choose from. You can choose different colors to decorate according to your own decoration style. How to maintain broken bridge aluminum profile doors and windows If you use it for a long time, it must be maintained. If you maintain it well, our doors and windows will not be prone to problems, and the use time will be longer. Let's take a look at how to maintain it. First of all, it is necessary to check the joints of the door and window frames and walls frequently. If there is any looseness, tighten the loose screws in time and fix them with glue and cement. Otherwise, it is easy to cause the overall deformation of the frame, and the doors and windows cannot be properly closed and sealed. Secondly, in the process of use, you should push and pull gently, and do not push or pull forcibly when you find that there is difficulty or stuck. You should troubleshoot first, and then push and pull. Then there's the matter of keeping it clean. Dust accumulation and deformation are the main reasons for the difficulty of pushing and pulling aluminum alloy doors and windows, so it is necessary to clean the doors and windows, especially the cleaning of the sliding grooves. In daily life, you can use a vacuum cleaner to absorb the dust accumulation in the groove and the top of the door seal to avoid accumulation.

Read More

Aluminum profiles have the advantages of energy saving and environmental protection, light weight, corrosion resistance, fast assembly, etc., covering a wide range of areas. Do you know the application range of industrial aluminum profiles? Construction: Aluminum profiles are not only exquisite in appearance, but also have strong corrosion resistance, and are widely used in the construction industry; such as: doors and windows, curtain walls, lighting roofs, partitions, decoration, etc. Electronic and electrical industry: Aluminum profiles are widely used in the electronics industry and belong to profiled materials. Aluminum has excellent heat dissipation function and is mainly used for radiators, wires, shells and other components. Transportation industry: Industrial aluminum profiles have the advantages of light weight, energy saving and environmental protection, and corrosion resistance. It is mainly used in automobile manufacturing and rail transportation such as automobile frames, automobile doors and windows, engine casings, components, high-speed railway carriage bodies and structural frames. Industrial manufacturing: Industrial aluminum profiles not only have their own mechanical structure, but also meet the bearing capacity knowledge of industrial manufacturing, have super tensile strength and toughness, and are widely used in industrial manufacturing, mainly including mechanical frames, fence systems, automatic transmission systems, Infrastructure Structural Frames, Shielding, Platforms, Assembly Line Consoles, etc. Aerospace: Aluminum profiles have superior bearing capacity, strength and wear resistance, which can not only effectively reduce their own weight, but also save energy.

Read More

Internationally, at present, multiple factors have led to the shortage of electricity supply in Europe. The power structure in Europe is mainly composed of natural gas, nuclear energy and renewable energy. Affected by the geopolitical situation, the supply of natural gas continues to decline and the price rises, which has caused huge pressure on European energy costs. The recent high temperature weather has led to increased evaporation of water in European rivers (lakes), lower water levels, and serious impacts on hydropower generation. The impact of high temperature on the power structure in Europe is comprehensive, which has also led to a record high electricity price in Europe, and smelters with high energy consumption will continue to face the threat of production shutdown. From the actual situation, the probability of a comprehensive production reduction in Europe is relatively low. Since September last year, the shortage of natural gas in Europe has led to a sharp increase in energy, and the production of electrolytic aluminum has been reduced. Up to now, the production of electrolytic aluminum in Europe has decreased by about 858,000 tons, accounting for about 20%. Under the extreme high temperature weather this year, there are mainly four regions of Slovakia, France, Germany and Greece that have reduced production, while Norway, Sweden and Iceland have low electricity costs and sufficient power supply, and the probability of production reduction is low. Therefore, it is optimistic that the production capacity of electrolytic aluminum in Europe will be reduced by 670,000 tons this year. If the high temperature continues until September, the scale of production reduction may be further expanded. From a pessimistic perspective, the production capacity reduction of electrolytic aluminum will exceed 800,000 tons. From the perspective of global supply, the reduction of electrolytic aluminum production in Europe will not have a particularly large impact on global supply, but it will have an impact on local spot premiums and discounts in Europe. Aluminum inventories remain depleted. If September is still affected by the high temperature, the reduction of electrolytic aluminum production will be further expanded, which may lead to a further increase in the premiums and discounts in major European consuming regions. At present, against the backdrop of low LME aluminium inventories, there may be a danger of short positions. After the off-season of consumption, considering that the pace of resumption of production on the supply side will be slower than that on the demand side, or there may be a phased destocking situation, which will bring about a short-term mismatch between supply and demand, especially in the Sichuan-Chongqing region, the spot premium and discount will be significantly higher. After the "Golden Nine Silver Ten" consumption peak season ends, the supply pressure will re-emphasize. With the advent of winter, the problem of energ...

Read MoreBecause of its own advantages, industrial aluminum profiles can be used in major industries. Now many companies need to ask the aluminum profile production and processing plants for prices when purchasing aluminum profiles, and the processing plants will quote them according to customer requirements. , Different aluminum profile processing plants have different quotations for the same aluminum profile. Why are the processing costs different for the same type of industrial aluminum profiles? What are the reasons? 1. The quality of aluminum profiles is different: many manufacturers with very low processing fees usually do not pay much attention to product quality. In terms of dimensional accuracy, the appearance and shape of aluminum profiles with poor quality cannot meet the requirements for use, which leads to price differences. . 2. The raw materials are different: in order to lower the price of aluminum materials, some processing factories use scrap aluminum or aluminum blending, regular enterprises will use the original aluminum ingots + the factory's head and tail materials, this effect will be reflected in the processing cost difference. 3. Different processing technology: The processing technology of the aluminum profile processing plant uses extrusion technology and aluminium extrusion equipment. The processing technology and mold manufacturing technology are different, and the prices are also far apart, which affects the price difference. 4. Packaging costs: Different packaging materials have different costs. Before delivery, aluminum profiles will be packaged with foam or kraft paper for small aluminum profiles, and large aluminum profiles (frame, workbench) will be packaged with wood. box for packing and shipping. The following recommendations are made to aluminum profile importers: 1. Sign a formal contract with the manufacturer to more effectively protect your own interests. 2. Before receiving the goods, verify the goods for inspection, and do not receive the goods carelessly. 3. It is still necessary to start from your own needs and tailor-made. Anhui Shengxin aluminum profile manufacturer has been focusing on the production and processing of aluminum profiles for 20 years, focusing on the production and processing of aluminum profile accessories, aluminum profile frames, assembly line workbenches, display rack structures, equipment frames, outdoor sun rooms, machine covers, protective barriers, safety fences, Aluminum profile workbench and industrial assembly line products, etc.

Read More online service

online service 0086 13635632360

0086 13635632360 sales@sxalu.com

sales@sxalu.com 008617309695108

008617309695108