0086 13635632360

0086 13635632360

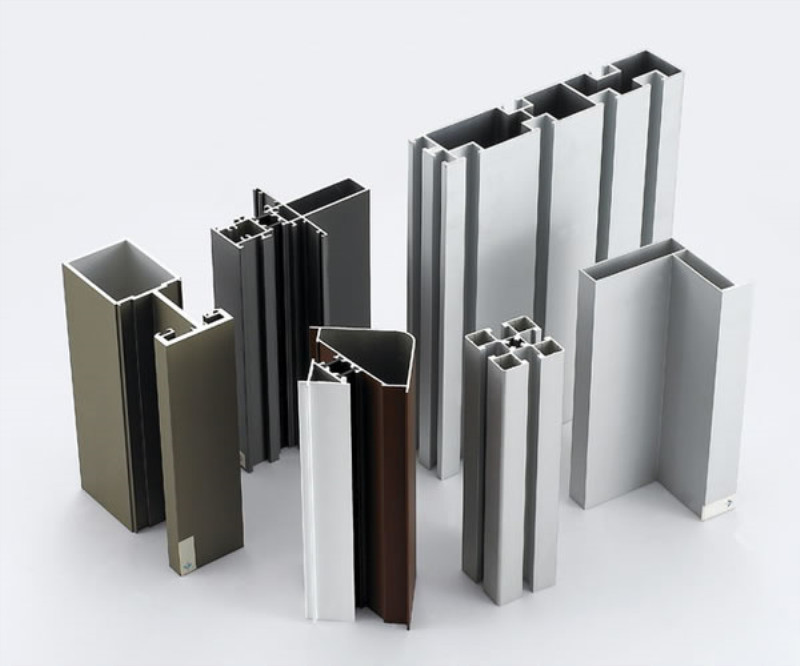

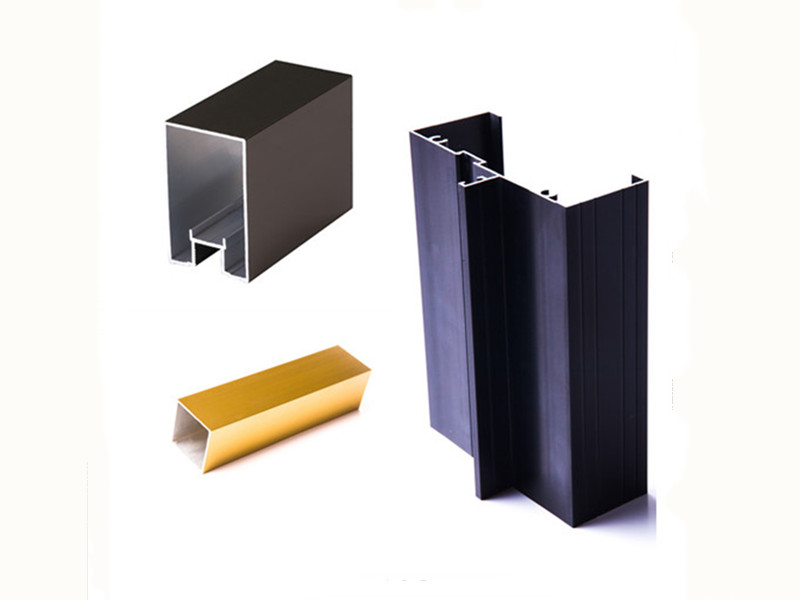

1, Check the product certificates, note the date of manufacture, specifications, technical conditions and production license number. 2, Check the thickness. Thickness of the Aluminum profiles for doors and windows should be not less than 1.2 mm. 3, Carefully observe the surface conditions of aluminum profiles, aluminum should be bright colors, good gloss, the surface can not have a clear scratches, bubbles and other defects are not acceptable on the aluminum profiles surface. 4, Pay attention to the thickness of the aluminum profiles surface coating, surface coating thickness for anodized aluminium extrusions shall not less than 10μm, electrophoretic coating aluminum product thickness of not less than 17μm, surface coating thickness for powder coating aluminium file shall not exceed the range of 40-120μm, Fluorocarbon paint coated aluminium profiles should be two or more, not less than 30μm. 5, The coastal areas users are suggested to choose the electrophresis,powder coated or fluorocarbon coated aluminum alloy profiles for better corrosion resistance.

Read More

Why should Aluminum profiles need to be powder coated and anodized? Onece the aluminium profile is powder coated or anodized, the aluminium profile become beautiful easy to clean. There is no welding process required to assemble powder coated aluminium profile, so the surface treated aluminium profiles are environmentally friendly and easy to install, remove and transport. This is the reasion why aluminium profiles are widelyly used in building and industrial. As the aluminum alloy is light, easy to process and high mechanical strength,the aluminium extrusion is widely used in building doors and windows, walls and other products. Meanwhile, aluminum has the following two characteristics: (1) The higher purity of aluminum alloy has better corrosion resistance, this is mainly because of a layer of dense natural oxide film generated faster on the pure aluminum surface in the air,this layer of anodized film played a protective role to preventing further corrosion of air, harmful gases and water. (2) The mechanical strength of pure aluminum is high, but the corrosion resistance is low. Although the corrosion resistance of pure aluminum is good, but the mechanical strength is poor, which restricts the application of aluminum, for which we made pure aluminum into various types of aluminum alloy, aluminum mechanical strength greatly improved, but unsurface treated aluminium profiles have the poor corrosion resistance than pure aluminum, which may be due to oxidation and corrosion. In summary, whether industrial aluminium profile or architectural aluminium profiles need to carry out surface treatment for protection through the powder coating and anodizing. In addition to a high corrosion resistance, the surface treated aluminium profile but also has a variety of colors and many other advantages corresponding to the accessories.

Read More online service

online service 0086 13635632360

0086 13635632360 sales@sxalu.com

sales@sxalu.com 008617309695108

008617309695108