0086 13635632360

0086 13635632360

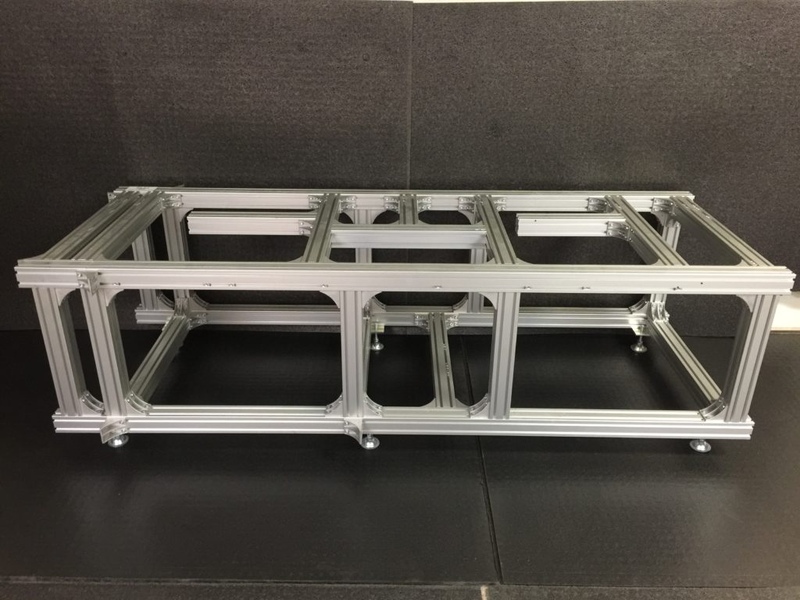

Most modern factory floors require workbenches, and many stainless steel and wood workbenches have been replaced by aluminum profiles. As a manufacturer of aluminum profiles and workbenches, let me first talk about what aluminum profiles are. Aluminum profiles are aluminum alloy materials with different cross-sectional shapes obtained by hot-melting and extruding aluminum rods. The production process of aluminum profiles mainly includes three processes: casting, extrusion and surface treatment. Among them, the surface treatment mainly includes: anodizing, electrophoretic coating, fluorocarbon spraying, powder spraying, wood grain transfer and other processes. Next we compare aluminum and steel. In the manufacturing sector, steel has always been a popular material because it is cheap and has a wide range of applications. However, steel also has many disadvantages, which are time-consuming and labor-intensive. And the steel connection needs to be welded, which costs a lot of money. In addition, the processed materials often cannot be completely matched, so it is necessary to reprocess them. When reprocessing is performed, even the re-investment of the machine is needed, which virtually increases the cost. And steel is much heavier than aluminum, which makes transportation and installation less convenient. Therefore, despite the low production cost of steel, inflexible processing can lead to shorter life and double production costs. Steel also needs regular anti-corrosion treatment, which still requires a lot of cost. The inflexibility of processing and the costs associated with high transport weights make it unprofitable to re-use materials that are no longer needed. But with aluminum, the situation is completely different. The material is highly flexible both in manufacturing and in use. Using aluminum will be more economical and environmentally friendly than steel. And the weight of aluminum is extremely light, only one third of steel, so the price is almost the same as steel. And also has a certain load-bearing capacity. The machining process is very simple, no special machinery and equipment are needed, and no deep training of employees is required. In addition, the aluminum profile workbench does not need to be welded, and is connected with a special matching connector, which can be disassembled and assembled at will to achieve secondary use. In addition, no corrosion protection measures are required, which reduces maintenance costs. Therefore, aluminum can be used instead of steel when the load requirements are not very high.

Read More

The Aluminium Formwork System for concreting is probably the most versatile modern construction system. Unlike other systems it is equally suited to both high and low rise construction. Specifically designed to allow the rapid construction of multiple unit projects at optimum productivity, the aluminium formwork can be used for a broad range of applications, from straightforward panels to more complicated structures involving bay windows, stairs and A/C hoods. The degree of pre engineering and inherent simplicity of the aluminium formwork enables unskilled foreign labour to be used. Every component is light enough to be handled by one operative, minimising the need for heavy lifting equipment. The Formwork is specifically designed to allow rapid construction on all types of architectural layouts. 1.Total system forms the complete concrete structure 2.Custom designed to suit project requirements 3.Unsurpassed construction speed 4.High quality finish 5.Cost effective for mass production 6.Panels can be reused over 100 times 7.Erected using unskilled labour 8.Light weight, easy to handle 9.Low waste

Read More

1. Anodizing: it can form a porous oxide film with a hardness of up to 500 HV; the oxide film with a porous structure can also absorb lubricants and pigments to enhance the corrosion resistance and wear resistance of the surface of the material; Insulation effect, can prevent breakdown voltage greater than 30V / μm; strong high temperature resistance, can withstand high temperature of 1500 ℃; use good adsorption capacity can be oxidized and colored into various decorative colors, widely used in aerospace, electronic appliances, Construction of various aluminum profiles and building decoration. 2. Electrophoretic coating: water is used as the dispersion medium, and the amount of co-solvent is small, which reduces the pollution of air and water, and there is no danger of fire; the paint has good swimming permeability and can cover the edges and gaps of aluminum profiles. Forms a dense and uniform oxide film, and the overall anti-corrosion ability is very strong; the appearance quality is high, no sagging phenomenon occurs, and no solvent is condensed on the surface of the profile to form a poor appearance; the advanced RO circulation system is adopted, so that the coating recovery rate is 98% More than%, waste water discharge is small, which not only saves chemical coatings, but also reduces environmental pollution. 3. Powder coating: The molecular weight of the resin used in powder coating is larger than that of solution-type coating, which makes the surface of the aluminum profile have good chemical resistance. The powder coating can obtain a coating of 50-300μm, which greatly reduces the number of painting It saves working time, there is no droop phenomenon and pinhole defects caused by solution-type coatings during coating, and it is possible to obtain better film layers to make aluminum profiles sturdy and durable; the colors are colorful and the decorative effect is improved; for aluminum The quality of the surface of the substrate and the quality of the pretreatment are not as strict as the first two treatment methods.

Read More

Defect characteristics of surface cracks on aluminum profiles: The surface of aluminum profiles exhibits longitudinal, fish-like, repetitive, intermittent breaks, which are severely disconnected. Causes of surface cracks in aluminum profiles: (1) The extrusion coefficient of aluminum profile is too large, the extrusion temperature is too high (rod, barrel, die three temperature), and the extrusion speed is too fast; (2) The squeezing force is unstable, suddenly high or low, or the speed difference between multiple speeds is obvious, and the speed change is sudden when shifting; (3) When the aluminum alloy profile is extruded, the head end presses (presses) too fast, the tail end runs or does not decelerate, and a large amount of aluminum penetrates into the dead zone; (4) The quality of the rod is poor, the rod is overburned, large grains, and loose. Pressure surplus (V3 aluminum) is too thin; (5) The design and manufacturing of the extrusion mold with a severe flow velocity ratio is unreasonable. Elimination of surface cracks on aluminum profiles: (1) Profiles with excessive extrusion coefficients can be produced on a small machine with an appropriate extrusion ratio; in addition, the extrusion temperature must be controlled strictly according to the production process requirements and an appropriate extrusion speed must be used; (2) The operator is concentrated, the speed is stable, the pressure cannot be high or low, and the manual operation is coordinated when changing gears; (3) The front and rear ends of the aluminum profile stoppage are dead zones or V3 volume (aluminum rod surface) aluminum, which has many impurities, poor quality, and insufficient viscosity, so the extrusion speed of the head and tail of the profile should be slowed down; (4) The surface of the aluminum rod should be fine and clean without oil stains, the internal organization must meet the standards, and the pressure surplus should remain normally (5% of the rod length); (5) The designer of the extrusion die shall design and manufacture a qualified die with uniform flow velocity.

Read More

Recently, the party branch of Anhui Shengxin Aluminum Co., Ltd. actively carried out learning activities for Comrade Li Xia, an outstanding Communist Party member of Xuancheng City. After the self-learning notice was issued, Shengxin Aluminum will use the WeChat platform and QQ group to release the learning materials in a timely manner. The party branch will also use the "three sessions and one lesson", party members self-study, symposium, etc. to organize the whole Party members and cadres and workers carried out activities to learn from outstanding Communist Party member Li Xia. Through a series of activities, the company's employees fully realize the importance of learning from outstanding people. Education guides the majority of party members to learn the professionalism of Comrade Li Xia's dedication and responsibility, and learns his noble feelings of keeping his mission and silent dedication. In the process of learning and education, everyone was moved by Comrade Li Xia’s deeds and his mind was greatly touched. Party members have expressed their willingness to use Comrade Li Xia as an example to firmly "four senses", carry forward the fine work style of dedication and courage, and further enhance the spirit of wanting officers, officers, and doing things, using practical actions and Excellent performance makes a greater contribution to the successful completion of the company's goals and tasks throughout the year.

Read More online service

online service 0086 13635632360

0086 13635632360 sales@sxalu.com

sales@sxalu.com 008617309695108

008617309695108