0086 13635632360

0086 13635632360

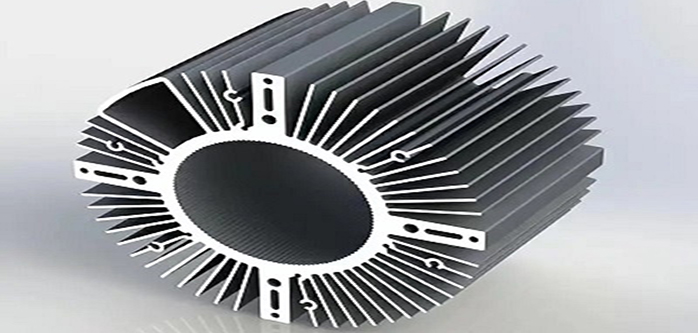

Our aluminum heatsink profiles are designed to provide optimal thermal performance while maintaining an attractive visual appearance. Utilizing state-of-the-art manufacturing techniques and materials, these profiles have been tested for performance and durability, ensuring they meet or exceed industry standards. We are proud to be the innovative leader in thermal management and look forward to continuing to provide high-quality aluminum heatsink profiles to meet your evolving needs. Contact us today to learn more! https://www.shengxinaluminium.com/shengxin-aluminum-tube-supplier-aluminium-extrusion-profiles_p554.html

Read More

With the continuous development of the manufacturing industry, finding efficient and durable production materials has become a top priority. The introduction of industrial aluminum extrusions has revolutionized the way the manufacturing process is done. Industrial aluminum profiles are lightweight, strong and customizable. They provide excellent solutions for a wide range of manufacturing needs, including automation, conveyor systems and workstations. Profiles come in a variety of shapes, sizes and designs, offering endless customization possibilities. One of the biggest advantages of industrial aluminum extrusions is their durability. They can withstand extreme temperatures, harsh conditions and high pressure, making them ideal for use in demanding industrial environments. In addition, industrial aluminum profiles are easy to assemble, disassemble and reassemble. They facilitate a fast and efficient manufacturing process, reducing downtime and increasing productivity. Overall, the launch of industrial aluminum extrusions was a game-changing event for manufacturers. It allows for a more versatile and efficient manufacturing process, ultimately leading to increased profits and higher quality products. rIf you want to learn more about our products, please click the link below: https://www.shengxinaluminium.com/industrial-aluminium-profile_c50

Read More

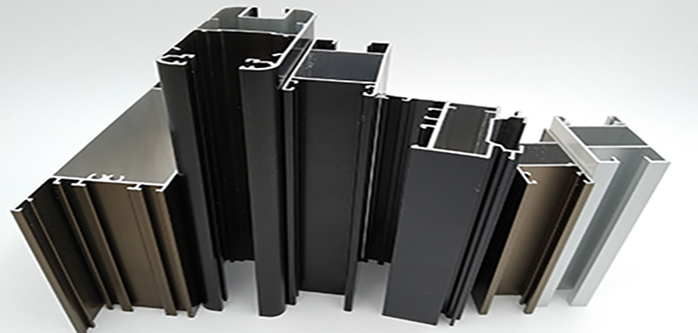

In the development of modern society, the development speed of the construction industry is very fast. With the continuous improvement of people's requirements for life, the requirements for materials during construction are also getting higher and higher, so the demand for the use of aluminum doors and windows equipment is also increasing , so what are the performance of this equipment? How to choose better? Let's take a look at these introductions. Aluminum doors and windows equipment performance: First of all, aluminum doors and windows are a very important processing equipment, so they are widely used in many fields. There are also various steps in the processing of aluminum doors and windows, including equipment cutting, welding, etc. Each equipment will have The corresponding equipment is used as a reference; professional manufacturers must consider the cutting and welding of the equipment when designing equipment, and each type of equipment has corresponding equipment as a reference during processing. In this way, the performance of aluminum doors and windows equipment can be well reflected in the corresponding layout, professional joint parts and positioning between parts, while ensuring the overall space requirements of the equipment, it also ensures more stable operation in the later stage. Secondly, when using this type of equipment, attention should also be paid to the processing performance. Therefore, in terms of stability control, corresponding materials should be used to improve the process stability of equipment processing. Of course, the processing performance can also be well reflected in the use of equipment. , The equipment also uses simplistic processing during operation. This design can help the equipment to make necessary considerations and connections. How to buy aluminum doors and windows equipment: When buying, you can’t just pay attention to the price, you must choose the corresponding product according to your own usage. In the market, there are many specifications and models of this kind of product, so you must choose the corresponding product according to your purpose of use and environment. product. We must pay attention to the services we provide, not only to ensure the quality of after-sales service, but also to ensure the pre-sales service and technical services. The above is the relevant introduction of aluminum doors and windows equipment. I hope that these contents can give you a better understanding of this equipment. Of course, if you want to give full play to its performance during use, you must not only choose high-quality equipment, but also pay attention to the quality of the equipment. The method of use and the maintenance and maintenance of the process of use, only in this way can the equipment be more valuable.

Read More

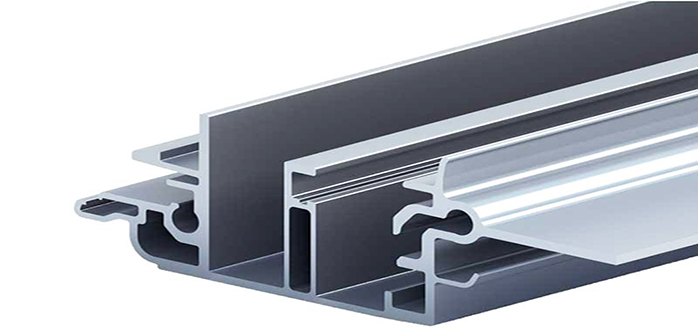

Custom aluminum profiles are becoming increasingly popular in modern manufacturing due to their versatility and cost-effectiveness. Unlike standard aluminum products, custom profiles can be designed to precise specifications, which allows for greater flexibility in product design and functionality. One of the main benefits of custom aluminum profiles is their ability to reduce overall manufacturing costs. By designing a custom profile that fits the exact needs of a particular application, manufacturers can minimize material waste and maximize production efficiency, resulting in lower costs per unit. Furthermore, custom aluminum profiles offer superior strength-to-weight ratios compared to other materials such as steel or wood. This means that products made from custom aluminum profiles can support heavy loads without adding excessive weight, making them an ideal choice for industries such as aerospace and transportation. Custom aluminum profiles also provide enhanced aesthetic appeal compared to standard aluminum products. They can be finished with various coatings to improve their appearance and durability, making them an ideal choice for architectural applications. In addition, custom aluminum profiles are highly recyclable, which makes them an eco-friendly choice for manufacturers who prioritize sustainability. Recycling aluminum profiles requires only a fraction of the energy needed to produce virgin aluminum, which reduces greenhouse gas emissions and conserves natural resources. In conclusion, custom aluminum profiles offer numerous benefits for modern manufacturing. From reducing overall costs to providing superior strength and aesthetic appeal, custom aluminum profiles are an excellent choice for a wide range of applications.

Read More

The automotive industry is undergoing major change as manufacturers seek to reduce vehicle weight to improve fuel efficiency and reduce emissions. One of the key technologies driving this trend is the use of aluminum profiles instead of traditional steel components. The benefits of using aluminum profiles in automobiles are numerous. For one, they are much lighter than steel, which means cars can be more fuel efficient and reduce emissions. Plus, aluminum profiles are extremely durable and corrosion-resistant, which means they can last for years without needing to be replaced. Aluminum profiles for automotive are used in a wide variety of automotive applications, from body panels and structural components to heat exchangers and suspension systems. By replacing heavier steel components with lightweight aluminum extrusions, automakers can reduce the overall weight of a vehicle without sacrificing safety or performance. As the automotive industry continues to evolve, it is clear that the use of aluminum extrusions will play an important role in driving innovation and sustainable development.

Read More online service

online service 0086 13635632360

0086 13635632360 sales@sxalu.com

sales@sxalu.com 008617309695108

008617309695108