0086 13635632360

0086 13635632360

Ahoy, fellow adventurers of the high seas! Rina Meng here, ready to set sail on a thrilling journey through the world of high-end aluminum alloys in ships and ocean engineering. Buckle up, my friends, because we're about to embark on a nautical adventure like no other. Get ready to discover the hidden treasures of aluminum's applications in the maritime world. Anchors aweigh! Let me start by sharing a little anecdote. Picture this: you're standing on the deck of a magnificent ship, the wind in your hair, and the salty sea breeze filling your lungs. It's like a scene straight out of a swashbuckling adventure! But have you ever wondered about the materials that make these maritime marvels possible? Well, my friends, it's time to unveil the secrets of high-end aluminum alloys and their role in ships and ocean engineering. It's like discovering a treasure trove of possibilities! When it comes to ships, aluminum alloys take center stage. They come in various forms like aluminum-magnesium alloys, aluminum-magnesium-silicon alloys, and aluminum-zinc-magnesium alloys. It's like having a buffet of options, each with its own unique set of properties. These alloys find their way into different parts of the ship, from masts and portholes to chimneys and wheelhouses. It's like a symphony of aluminum, playing a crucial role in the ship's structure and equipment. Let's talk portholes, my friends. The superstructures of ships rely on 6063 aluminum alloys for those sleek and sturdy portholes. It's like having a window to the world, allowing natural light to flood in and offering breathtaking views of the open sea. And when it comes to masts and gangways, 6063 and 6061 aluminum alloy profiles take the stage. It's like having the perfect balance of strength and durability, ensuring smooth sailing for the crew and passengers alike. But hold on tight, because we're about to dive deeper into the ocean of possibilities. The hull structure of ships is where aluminum alloys truly shine. Bulkheads, ribs, keels, bottom shells, and sides all benefit from the exceptional properties of these alloys. It's like building a fortress that can withstand the mighty waves and unpredictable tides. Among the aluminum-magnesium alloys, 5454 and 5052 take the lead as the main materials for manufacturing decks. It's like having a solid foundation that guarantees stability and safety. Now, let's set our sights on military ships. The quest for lighter ship structures has led to the widespread use of aluminum alloys in the field of military ships. It's like a secret weapon, giving our naval forces an edge in speed, precision, and cost-effectiveness. Fast attack craft, auxiliary military airships, and patrol boats all benefit from the lightweight advantage of aluminum alloys. It's like having a fleet of agile warriors ready to defend our shores. But wait, there's more to the aluminum adventure! It extends beyond ships and into the realm of marine engineering. Take, for example, the applicatio...

Read More

Hey there, folks! Rina Meng here, ready to take you on a wild ride through the captivating world of the Aluminum Extrusions Market. Buckle up, because we're about to dive deep into this industry's potential, trends, and oh-so-exciting challenges. Get ready to have your mind blown! So, what the heck are aluminum extrusions, you ask? Well, my friends, they're like the superheroes of the metal world. Picture this: you take some heated aluminum billets and push them through a die to create these incredible cross-sectional profiles. It's like molding aluminum into all sorts of shapes and sizes, from simple rods and bars to intricate structural components. It's like playing with Play-Doh, but on a whole new level! Now, let's talk numbers. Brace yourselves for some mind-boggling stats. The aluminum extrusion market is projected to grow at a steady compound annual growth rate (CAGR) of 4.6% from 2023 to 2033. That's like a rollercoaster ride of success, my friends! We're talking about a market that's estimated to be worth a jaw-dropping US$ 126.67 billion in 2023 and is expected to skyrocket to a mind-blowing US$ 195.48 billion by 2033. That's some serious moolah! But why is the aluminum extrusions market experiencing such a boom? Well, let me break it down for you. First off, aluminum extrusions are lightweight. It's like the featherweight champion of the metal world, making it perfect for industries that value efficiency and fuel economy. Think about it—automotive, aerospace, and even electronics. They all want to shed those extra pounds and soar to new heights! And let's not forget about durability. Aluminum extrusions are like the Hercules of metals, with their incredible strength and resistance to corrosion. They can withstand the test of time, enduring harsh conditions and still coming out on top. It's like having a superhero by your side, protecting your structures and ensuring they stand tall for years to come. But here's the real kicker—versatility. Aluminum extrusions are like the chameleons of the metal world, adapting to any situation you throw at them. They can be molded into any shape or size, allowing for endless possibilities in design and functionality. It's like having a magic wand that transforms metal into whatever you desire. From construction to transportation, they're there, making our lives easier and our industries thrive. Now, let's talk about sustainability. It's like the buzzword of the century, and aluminum extrusions are right there, leading the charge. They're like the eco-warriors of the metal world, contributing to sustainable design and reducing our carbon footprint. They're recyclable, energy-efficient, and have a lower environmental impact compared to other materials. It's like a win-win for Mother Earth and our industries. Who said you can't save the world one extrusion at a time? But hey, let's not forget the challenges we've faced along the way. It's like a never-ending game of hurdles and obstacles. From fluctuatin...

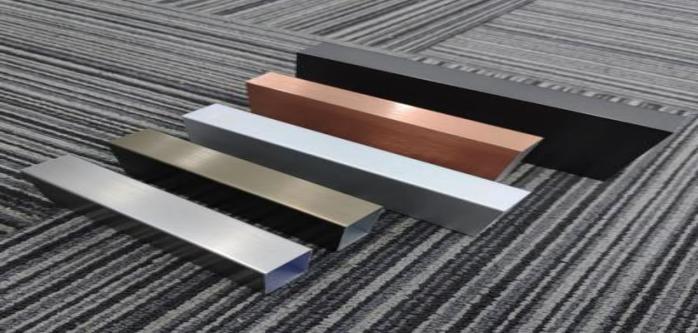

Read MoreHey there, design enthusiasts! Rina Meng here, your go-to gal for all things aluminum decor. Today, we're diving headfirst into the world of aluminum alloy U-shaped decorative lines. Trust me, these lines are the real deal when it comes to sprucing up your space with style and functionality. So, buckle up and get ready for a wild ride through the advantages of these beauties! Let me start by sharing a little personal story. Picture this: I was working on a home renovation project, trying to find the perfect finishing touch for the corners and ground. That's when I stumbled upon aluminum alloy U-shaped decorative lines. And let me tell you, it was love at first sight! These lines are like the superheroes of the decor world, balancing visual aesthetics, protecting corners, and adding that extra oomph to any space. One of the superpowers of aluminum alloy U-shaped decorative lines is their lightweight nature. They're like the featherweight champions of the decor universe, reducing the external load on high-rise buildings. And let's not forget about their excellent color performance, heat insulation, sound insulation, and waterproof properties. It's like they're a one-stop-shop for all your decor needs, providing both style and functionality in one sleek package! But the advantages don't stop there, my friends. The construction operations of these U-shaped wonders are a breeze. It's like a walk in the park, making transportation, installation, and cleaning a piece of cake. And let's not forget about the incredible processing performance of aluminum alloy U-shaped decorative lines. They come in various colors, giving you the freedom to let your creative juices flow. It's like having a magical color palette at your fingertips, ready to bring your design dreams to life! Now, let's talk about the design possibilities. Aluminum alloy U-shaped decorative lines are like the Picasso of the decor world, giving you endless options to play with. They can easily adapt to complex shapes, curves, and different types of processing. It's like they're saying, "Bring it on! I can handle any design challenge you throw at me!" These lines are all about pushing boundaries and expanding the horizons of your decor vision. But wait, there's more! Aluminum alloy U-shaped decorative lines are not only stylish but also safe and environmentally friendly. They're like the eco-warriors of the decor realm, giving you peace of mind while adding that wow factor to your space. And let's not forget about their durability. These lines are built to last, with high strength, no deformation, and resistance to water, moisture, collision, insects, and aging. It's like they have an invisible shield, protecting your decor from the wear and tear of everyday life! Overall, my design-savvy pals, aluminum alloy U-shaped decorative lines are a game-changer in the world of decor. They bring together style, functionality, and versatility like no other. So, if you're looking to jazz up your space wit...

Read More

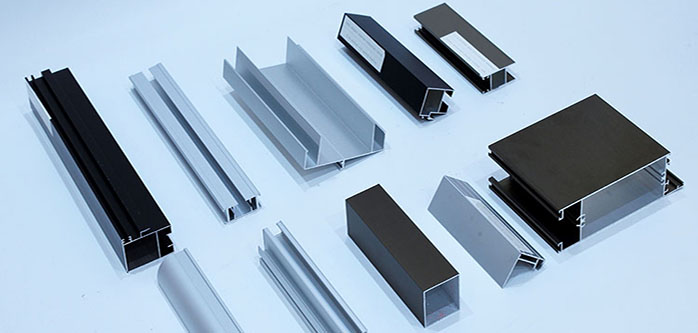

Hey there, news junkies! Rina Meng here, bringing you the hottest scoop in the world of construction. Today, we're shining the spotlight on the incredible impact of aluminum profiles. Brace yourselves for a riveting tale of innovation, versatility, and sustainable construction practices. Let's dive right into the news! Aluminum Profiles: The Game-Changers in Construction In a world where construction is king, aluminum profiles have emerged as the ultimate game-changers. These sleek, lightweight, and durable wonders are transforming the way we build, offering a myriad of benefits that traditional materials simply can't match. From skyscrapers to residential homes, aluminum profiles are leaving their mark on the architectural landscape. Unleashing the Power of Versatility One of the key factors behind the rise of aluminum profiles is their unparalleled versatility. These profiles come in a wide range of shapes, sizes, and designs, making them a dream come true for architects and designers alike. Whether it's sleek window frames, sturdy door frames, or intricate curtain walls, aluminum profiles can be customized to fit any project's unique requirements. It's like having a box of building blocks, allowing construction professionals to unleash their creativity and bring their visions to life. Strength Meets Sustainability But wait, there's more! Aluminum profiles not only offer aesthetic appeal but also pack a powerful sustainability punch. Unlike their counterparts, these profiles are lightweight, reducing the overall weight of structures and minimizing the need for excessive support. This translates to significant energy savings during transportation and installation, reducing carbon emissions and promoting eco-friendly practices. It's a win-win for both builders and the environment! Aesthetics That Wow Gone are the days of mundane construction designs. With aluminum profiles, the sky's the limit when it comes to aesthetics. These profiles can be anodized or coated with a variety of finishes, allowing for endless color options and textures. Want a sleek silver finish or a bold pop of color? Aluminum profiles have got you covered, adding that extra oomph to architectural masterpieces. The Durability Factor When it comes to durability, aluminum profiles are the undisputed champions. These profiles are corrosion-resistant, ensuring longevity even in harsh weather conditions. They can withstand the test of time, maintaining their structural integrity and aesthetic appeal for years to come. It's like having a superhero protecting your building from the elements! Embracing Efficiency and Cost Savings Last but not least, aluminum profiles bring efficiency and cost savings to the table. Their lightweight nature makes them easy to handle and install, reducing labor costs and construction time. Additionally, aluminum profiles require minimal maintenance, saving both time and money in the long run. It's a win-win for project managers and budget-conscious clien...

Read More

Hey there, aluminum aficionados! Rina Meng here, your trusty guide through the fascinating world of aluminum profiles. Today, we're diving deep into the sizzling topic of the working temperature of the aging furnace for different aluminum profile products. Get ready to feel the heat and discover the secrets behind achieving those flawless aluminum profiles. Let's jump right in! Now, picture this: you're in the heart of an aluminum production facility, surrounded by the hum of machinery and the scent of molten metal. It's a world where precision and heat dance hand in hand, creating aluminum profiles that are as strong as they are beautiful. And at the center of this fiery symphony lies the mighty aging furnace. So, what's the deal with this aging furnace, you ask? Well, my friend, it's the secret sauce that gives aluminum profiles their strength and durability. It's like a magical oven, where the profiles go in all soft and malleable, and come out as tough as nails. But here's the catch: different profile products require different working temperatures in the aging furnace. Let's break it down, shall we? 1. Ordinary Curtain Wall Profiles, Ordinary Door and Window Profiles, and Industrial Profiles: These bad boys all get cozy together in the same aging furnace. The temperature inside is carefully controlled within the range of 195±5 degrees. Once the furnace reaches this temperature, it's time to keep things toasty for 3 hours. Then, it's showtime! The profiles are released from the furnace, and a fan kicks into action, blowing cool air for 20 minutes. It's like giving those profiles a refreshing breeze after their hot spa treatment. Finally, a quality inspector steps in to check the hardness, making sure those profiles are as strong as they need to be. 2. Heat Insulation Curtain Wall Profiles and Heat Insulation Door and Window Profiles: Now, these profiles have their own special requirements. They, too, cozy up in the aging furnace, but this time, the temperature is controlled within the range of 180 ± 3 degrees. Once that temperature sweet spot is reached, it's time for a 3-hour warm-up session. After that, the profiles bid farewell to the furnace, and guess what? The fan makes its grand entrance once again, blowing cool air for 20 minutes. It's like a cool-down party for those heat insulation profiles. And of course, the quality inspector steps in to check the hardness, ensuring those profiles are up to snuff. 3. Mixing It Up: Now, what happens if you've got some aging and heat-insulating profiles, but the furnace isn't completely full? No worries, my friend! You can pop in 1 to 2 frames of ordinary profiles (with a wall thickness below 2.0mm) right alongside the heat-insulating profiles. It's like a little mingling party in the aging furnace. And the aging process? It follows the heat-insulating profile process, ensuring that all profiles get the love and attention they deserve. 4. Hanging in There: When it's time to hang those profiles into ...

Read More online service

online service 0086 13635632360

0086 13635632360 sales@sxalu.com

sales@sxalu.com 008617309695108

008617309695108