Aluminum profiles are versatile building materials that have revolutionized manufacturing and construction industries worldwide. Their strength, durability, and flexibility make them an ideal choice for many applications.

At the heart of aluminum profile production is a sophisticated manufacturing process that uses cutting-edge technology to create custom profiles for different industries. The process involves melting aluminum ingots, extruding the molten metal through a die, and then cutting and finishing the profiles to customer specifications.

The result is a high-quality product that meets industry standards and can be used for various applications. From the construction of buildings and bridges to the fabrication of industrial equipment and consumer products, aluminum profiles play a significant role in many industries.

One key benefit of aluminum profile production is its sustainability. Aluminum is a highly recyclable material, and the production process consumes less energy compared to other materials such as steel or plastic. This makes it an eco-friendly choice for companies looking to reduce their environmental impact.

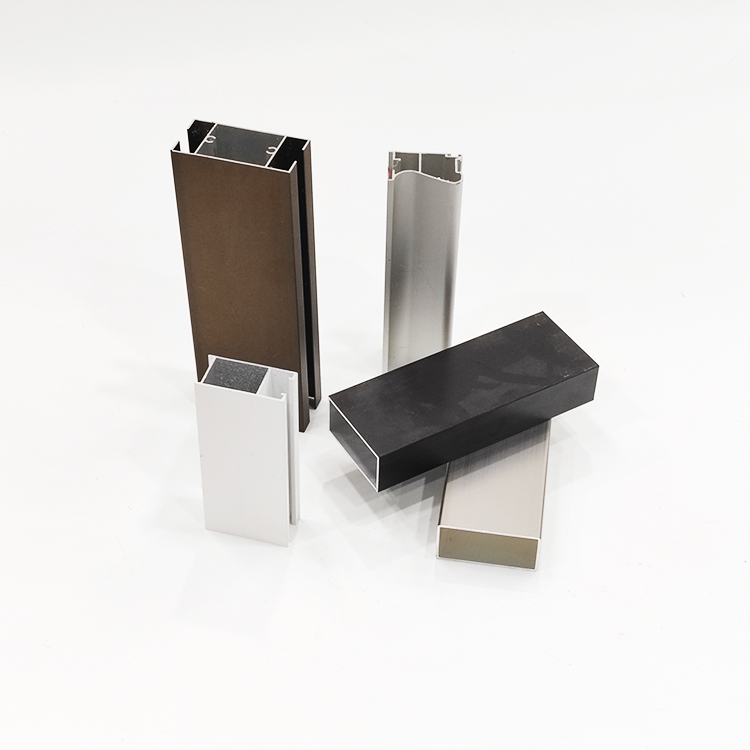

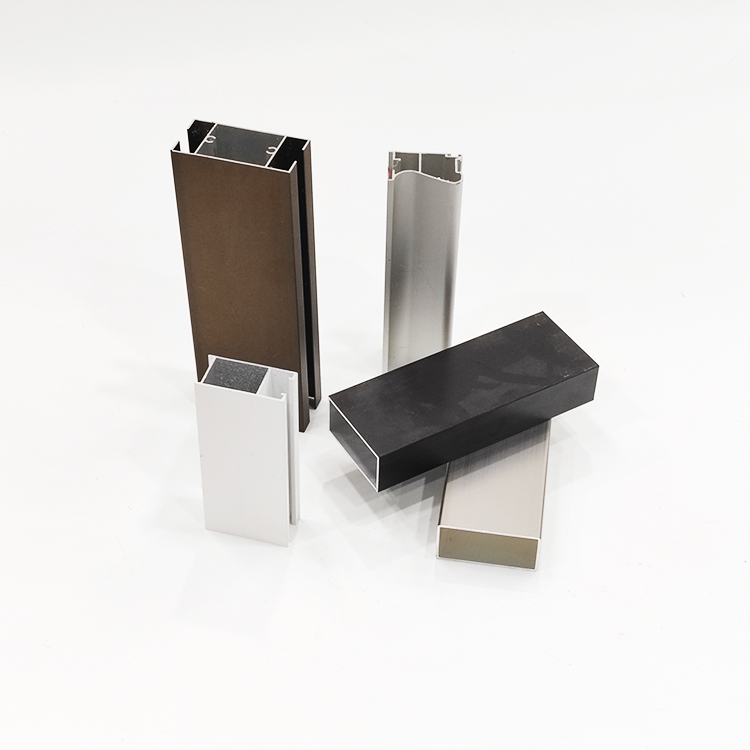

Another advantage of aluminum profiles is their versatility. They can be customized to meet specific customer requirements, including size, shape, and surface finish. This allows manufacturers to create unique profiles that meet the needs of their customers.

The use of aluminum profiles has also contributed to the development of lightweight and durable products. Industries such as automotive and aerospace rely heavily on aluminum profiles due to their high strength-to-weight ratio, making them ideal for components that require a high level of performance.

In conclusion, aluminum profile production is a critical process that has revolutionized many industries worldwide. Its strength, durability, and sustainability make it an ideal choice for many applications. As technology advances, we can expect even more innovations in aluminum profile production, paving the way for a more sustainable and efficient future.

online service

online service 0086 13635632360

0086 13635632360 sales@sxalu.com

sales@sxalu.com 008617309695108

008617309695108